2026 Anhui Guotai Aluminum Co.,Ltd All Rights Reserved.

Common problems and problems of aluminium alloy doors and Windows

Door and window hole must have drip line, before installation should check first.Because the rainwater that flows through the metope that makes of sea sand has very strong corrosive, must be prevented.

1. engineering design1, engineering design must be strength design calculation and test, according to the standard atlas and profile only manufacturer to provide the type of test report for production, installation and acceptance, that is wrong and even dangerous behavior.Because the standard atlas is only a series of window type of the large partition diagram, it does not indicate the load that can be borne by the construction according to the drawing, so it cannot be used as the basis of production, installation and acceptance.For different series of doors and Windows, it is necessary to check the strength, deflection or test according to the principle of the most unfavorable stress state.

2. The strength and stiffness of floor Windows and doors are generally insufficient, and the main stressed columns (beams) should be strengthened.

3. When the height of external doors and Windows of high-rise buildings is >30M, it shall be implemented in accordance with GB511057 lightning protection design code for buildings.Selection of two materials

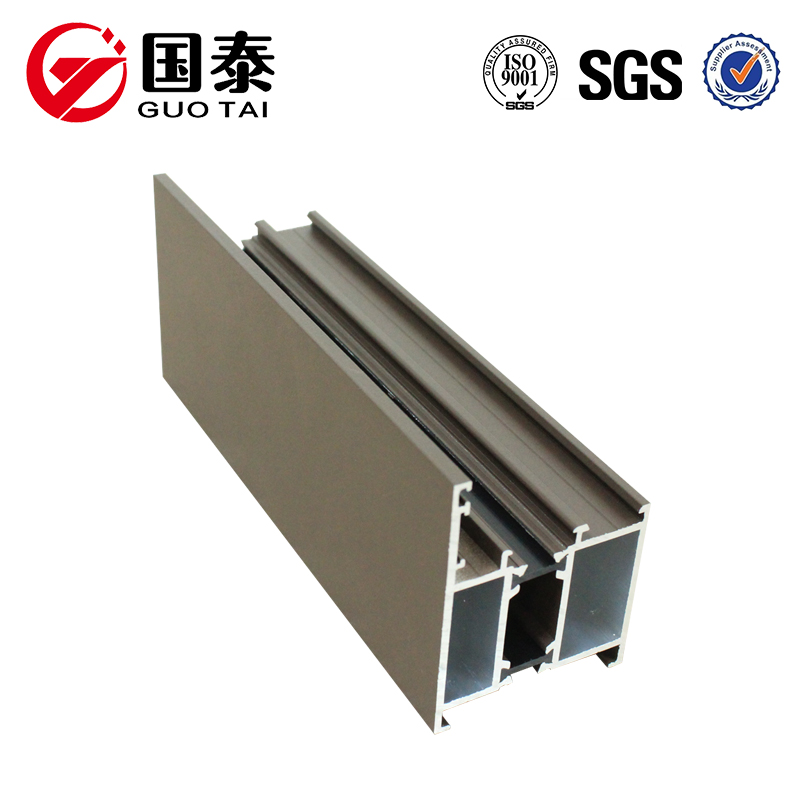

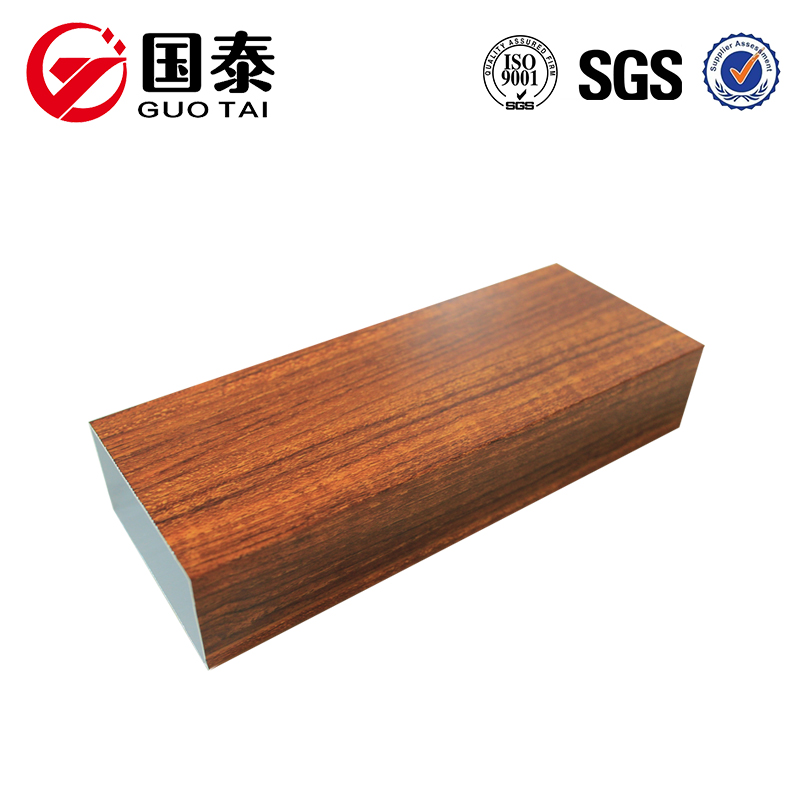

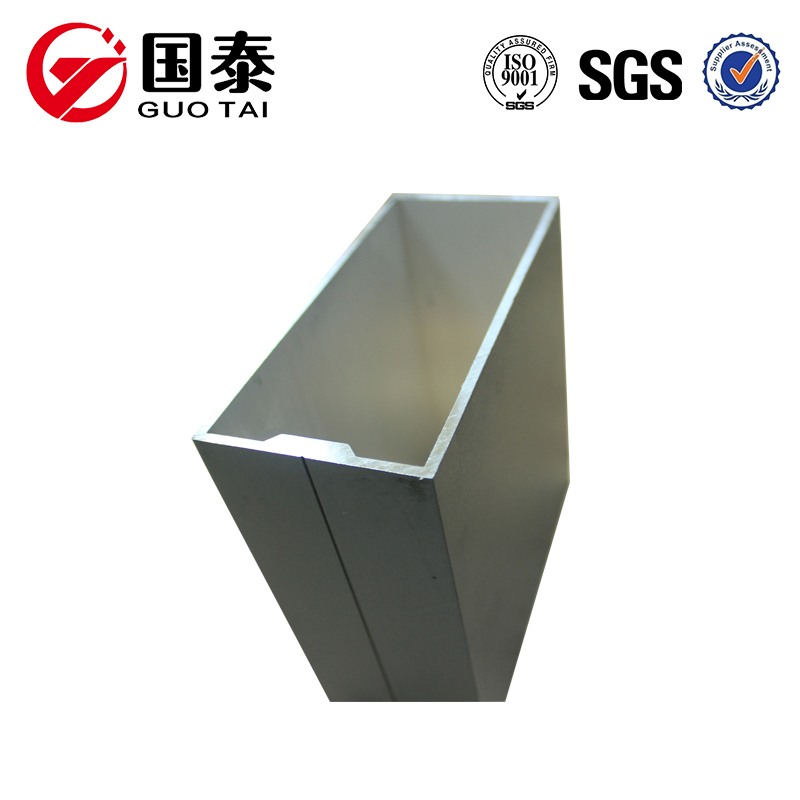

Aluminum alloy profiles must meet the requirements of GB/ t5237-2400 "aluminum alloy building profiles".

The selection and configuration of hardware accessories is one of the important factors to ensure the quality of Windows and doors.Even if it is the window type with good performance, also must rely on the choice and configuration of high quality fittings to ensure.

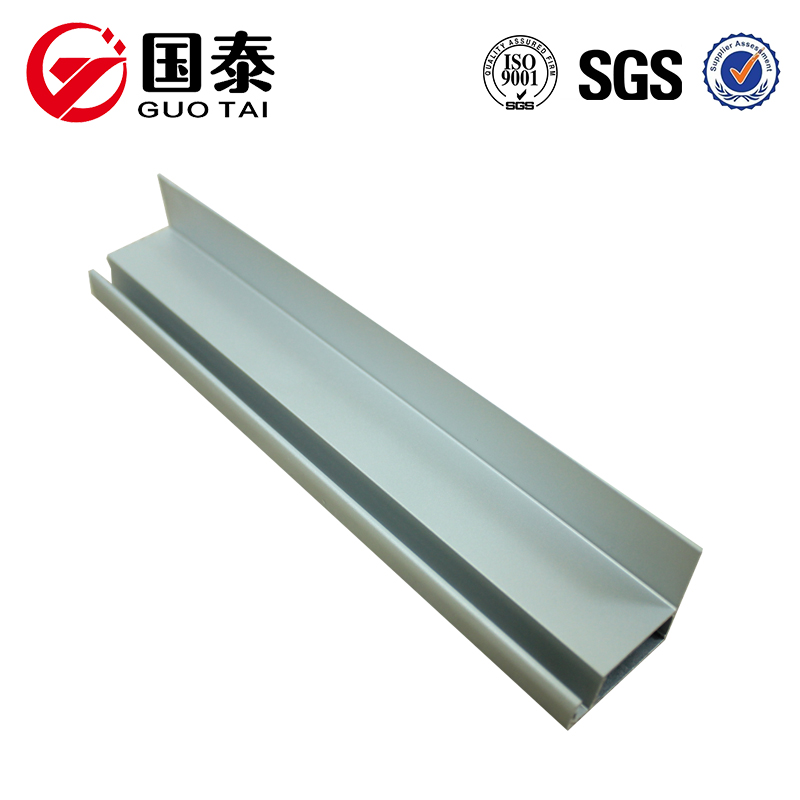

The pulley of sliding door window, woolen sliver, anti-falling sealing device, lower sealing block are more important fittings to ensure the quality of sliding door window.Pulley is the key to the smooth opening and closing of doors and Windows.Anti-falling sealing device is the safety guarantee to prevent the window fan from falling off. It also has the sealing function between the hook and the upper slide. ABS plastic with good durability ratio and epdm rubber should be used.The lower seal block ACTS as a seal between the hook and the glide path, which can effectively prevent water splashing under the action of fluctuating load.Wool is the seal of window fan and window frame, decide the advantage and disadvantage of window air tightness, common chemical fiber wool will curl when meeting water and lose sealing function, must use silicon wool.

The sealing tape between the hinge (or sliding window friction hinge), the handle and the frame fan is the most important part to ensure the quality of the open window.Hinges or sliding friction hinge brace the window of the bearing capacity is related to the security and the key to whether smooth opening and closing doors, Windows, carrying capacity is stronger than the friction hinge hinge, hinge frame can be made larger so casement, friction hinge is only applicable to frame a smaller window or on the window.Hand relates to the Windows security and sealing performance of the important parts, ordinary hand only applicable to frame and load are used on smaller casement, Europe type multipoint hand can be used for a wide in the frame and load on the casement of use;The sealing tape between frame fan is the guarantee of air tightness and water tightness of open doors and Windows.The recycled PVC strips do not have the sealing effectiveness and are ideal for the use of weather-resistant rubber such as ternary ethylene-propylene.

The model, specification and performance of hardware accessories shall conform to the relevant provisions of the current national standards.6. The structural glue and weather-resistant glue used in the hidden frame window should be tested for

compatibility with the profiles and glass before use.Three processing

1. The processing and production of aluminum doors and Windows shall be carried out in the factory and shall not be made at the construction site.

2. The processing of drain holes on the sliding way of sliding Windows should follow the principles of inner fan outer hole and outer fan inner hole, so as to ensure the sealing performance of Windows and Windows, especially the horizontal sliding window with horizontal orientation of the bottom horizontal sliver.

3. Before the aluminum doors and Windows are assembled, the burrs at the end should be removed, and sealing measures such as waterproof glue should be adopted at the end joints and the section joints to prevent the structure from seepage.

4. The structural assembly components of the hidden window must be made and maintained in the purification room.Dust, oil stains and other contaminants that bind to the surface of glass and aluminum frames must be removed with solvent;For each component or piece of glass cleaned, a clean dry cleaning cloth shall be replaced.The solvent should be poured onto the cloth. It is strictly prohibited to rub the cloth against the bottle mouth.The glue injection must be full, no bubbles or leakage, and the surface of the glue seam should be smooth and smooth.The glue remaining in the glue seam shall not be reused.Installation and product protection1. Before installation to Windows and doors hole shape and position accuracy of lofting, check the number and location of embedded concrete meets the design requirements, the top window is connected to the lightning protection zone, according to the rules for the unqualified parts should supervise and urge the construction unit.

Next: No